Call us today for a FREE CONSULTATION

Soil Stabilization

Full Depth Reclamation (FDR)

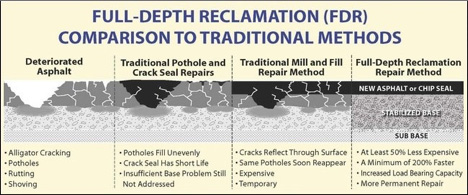

This process rebuilds worn out asphalt pavements by recycling the existing roadway. The old asphalt and base materials are pulverized, mixed with Portland Cement or Quick Lime and water, and then compacted to produce a strong, durable base for either a new asphalt or concrete surface.

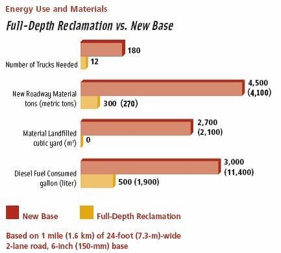

Full-depth reclamation uses the old asphalt and base material for the new road. There's little to no need to haul in aggregate or haul out old material for disposal. Truck traffic is dramatically reduced, and there is little or no waste.

Recycling Saves Money and Natural Resources

Full-depth reclamation uses the materials from the existing deteriorated asphalt pavement and, with the addition of cement or lime, creates a new stabilized base.

The recycled base will be stronger, more uniform, and more moisture resistant than the original base, resulting in a long, low-maintenance life. And most important, recycling costs are normally at least 25 to 50 percent less than the removal and replacement of the old pavement.

Material Conservation: A Wise Choice

Conserving virgin construction materials through recycling with cement makes smart economic and strategic sense. A century of modern growth and urbanization in America has depleted once plentiful aggregate supplies. Frequently, aggregates either come from distant quarries at great expense or from local sources offering only marginal quality. Continuing to exhaust these valuable resources to rebuild existing roads only propagates and accelerates the problem. Additionally, if old asphalt and base materials are not recycled, they must be disposed of or stockpiled, increasing transportation costs and utilizing valuable landfill space. In some locales, old asphalt can no longer be landfilled. Environmental laws are becoming stricter, thus adding to the expense of mining new materials and landfilling old.

Services